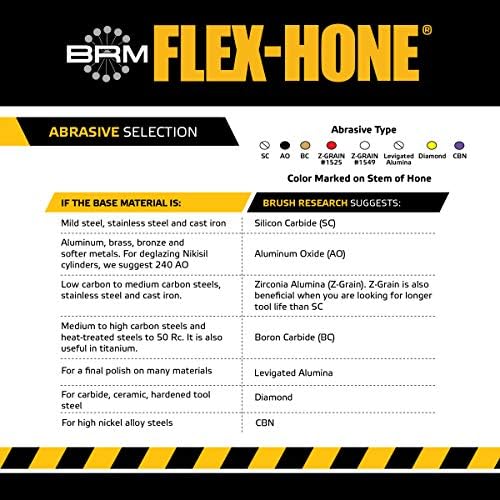

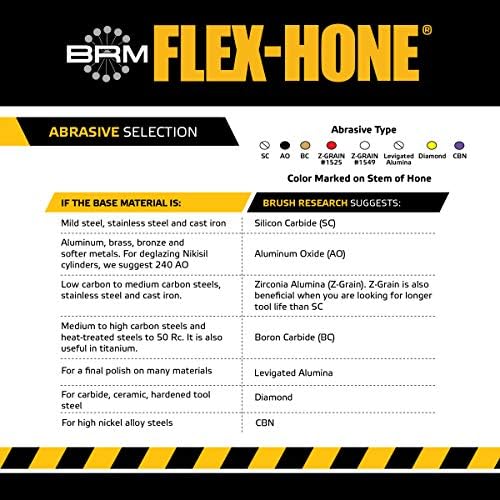

Brush Research FLEX-HONE Cylinder Hone, GB Series, Silicon Carbide Abrasive, 4-1/8 (105 mm) Diameter, 240 Grit Size

-

david

> 3 daygood price worth it

-

S. Ziemba

> 3 dayI bought this for my 1997 SeaDoo Speedster engine repair. I originally honed it with this but then found out I needed to get the cylinder bored over for other reasons. I took it into the machine shop and the machinist was in awe how amazing the cylinder looked he was wondering why I was even there. The cross hatch this tool leaves is second to none. This is a must have for anyone who regularly works on engines, but keep in mind these are fitted for specific size bores. If you just need one for a different size bore every time on new engines you work on, it might not be cost effective for you. For me, I would rather accumulate a whole set...so its all good for me.

-

Robert L. Queberg

> 3 dayUsed to hone cylinder bores on engine rebuild. Nice cross-hatch finish.

-

Darbman

Greater than one weekEasy to use and did the job perfectly. Will be getting more when I need them.

-

Kelly D

> 3 dayChucked it up in my drill, steady speed & motion, perfect results. Happy camper.

-

Griers

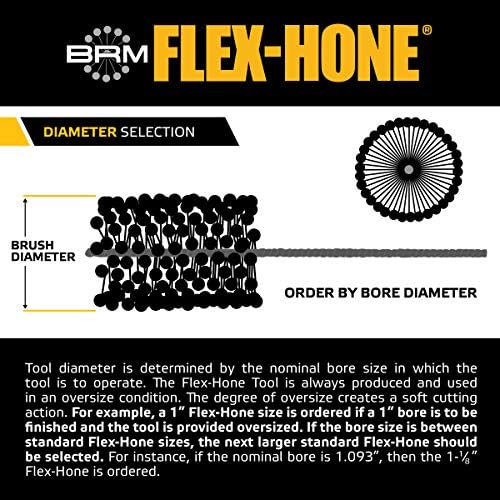

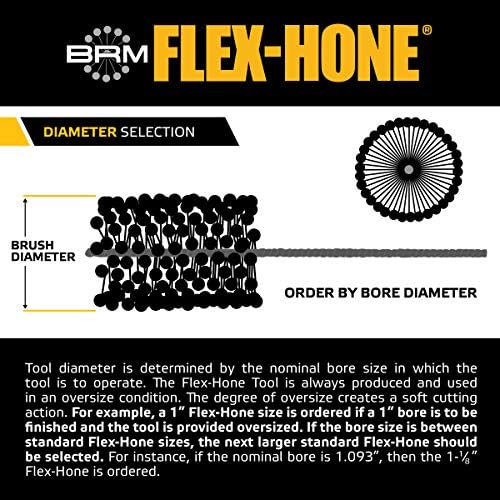

> 3 dayWow such and easy tool too use. I honed out some deep scratches and gave it a perfect cross hatch. My bore is was 2.9 and I bout the 31/4.

-

Tyson

> 3 daydeglazed my cylinders, and got it to work with my engine still in the car. only had to shorten it up

-

Eric S Woodring

> 3 dayIf your looking at buying it, then you know what it does. I hope your engine livesca long, happy life.

-

Colton Henninger

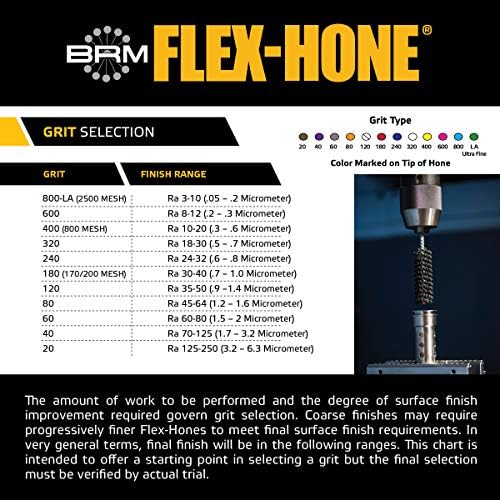

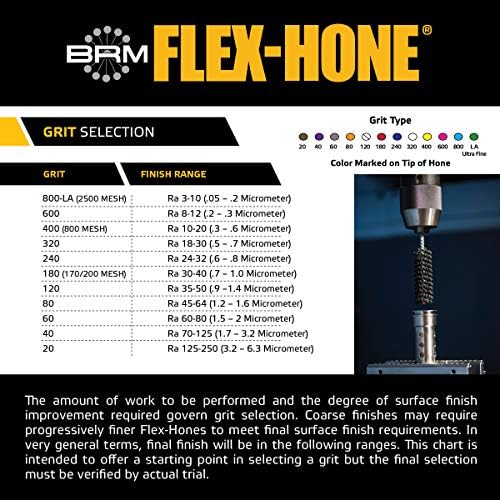

Greater than one weekOrdered a few different grits to take out some gunk and pits from an engine i am working on. You can definitely see the improvements and new life these products can provide under the right circumstances. Sadly for my case the damage to my engine is more than i feel comfortable dealing with, with a hone at least. Will be buying these products in the future for sure!!

-

Angie

> 3 dayStock engine refresh 4.0in bore. This thing worked great. Tip: Get a buddy and make them keep it flooded with lube while you stroke it;) Use wd40 or whatever is cheap. Youll use most of a can. Then wash that engine with soapy water and a brush, or just pressure wash it. Its going have lots of fine metal particles everywhere from the hone process.