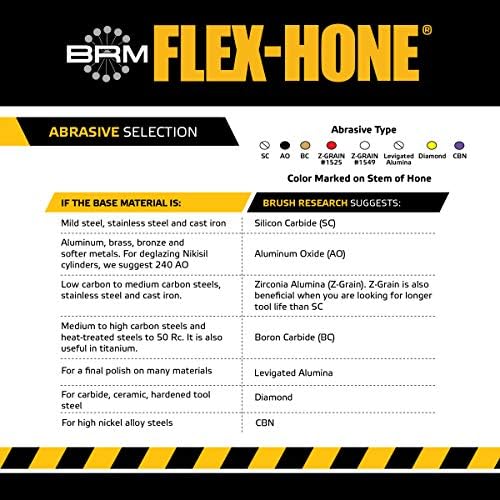

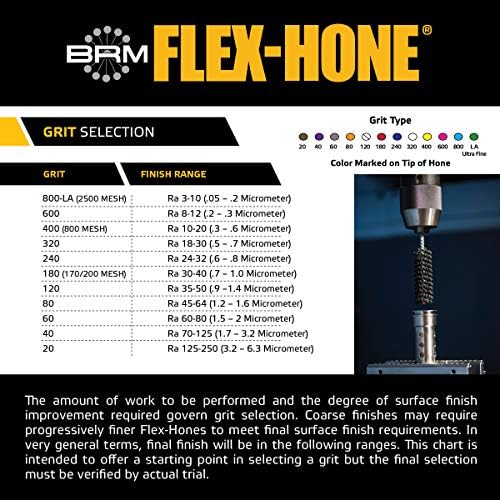

Brush Research FLEX-HONE Cylinder Hone, GB Series, Silicon Carbide Abrasive, 4-1/8 (105 mm) Diameter, 240 Grit Size

-

eaglewrench

> 3 dayUsed this to freshen up a cylinder on my Jetta TDI. Had one piston melt down and replaced it with a used one. This took most of the scoring out of the cylinder and the car runs again.

-

ANDY

> 3 dayShould be in all tool boxes

-

jason wysong

> 3 dayI bought this because the idiots i work with pretend to be LS experts. So far everything theyve said has been wrong. They said LS engines cylinder walls will be ruined with a ball hone. So I bought the best ball hone which comes sized perfectly for my engine Im building. Makes perfect cross hatchs. Good product.

-

spyderrider

Greater than one weekdont have a lot of experience with honing, so nothing really to compare it to. there is a technique to get the right cross hatch pattern. just used it to clean up the cylinder wall when installing new rings. have to move it quickly depending on the drill speed, but it left a really nice pattern and cleaned it up really nice. its quite aggresive so it only takes a few seconds. be careful

-

Bob

> 3 dayI made sure to order the correct size. I modified the end by grinding off the nub so I could get closer to the pistons. It worked excellent. The stones are quality, I sprayed with WD-40 and it made quick work of it leaving a beautiful cross hatch pattern deglasing perfectly.

-

Elmira West

Greater than one weekHave used these for years building subaru motors and yet to have an issue. Great product

-

BT8850

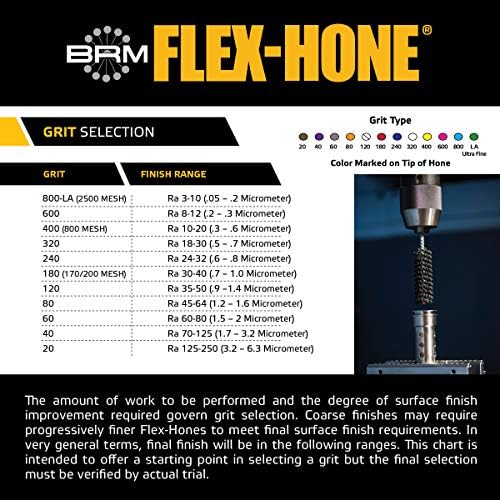

> 3 dayExcellent product. Brush hones are a very good thing to have around and BRM makes about the best ones. The price on amazon is inline with just about everywhere else so cant complain there. I used this particular hone on a standard bore small block ford engine block to hone the cylinders before I installed the pistons and rings. The 180 grit has worked great for me with standard Iron piston rings. If youre using moly rings or something else, refer to the manufacturers recommendation when choosing grit size. I also like the brush hones because you can purchase one for less than a machine shop will charge you to hone your cylinders, and you can usually do more than one block with one. The last BRM hone I had did 5 small blocks and still has some life in it. Take that for what you will. Very good product at a very good price. Definitely recommend for your rebuild or re-ring project!

-

J. Shade

> 3 dayFast, easy to use. I lubricated with transmission fluid. Took glaze off fast and left nice crosshatch. You must move quickly up and down. Lubricate hone between each cylinder.

-

Nicolas H.

> 3 dayEasy to use.

-

Akruck

11-06-2025Just used it on one aircraft cylinder, but it did an amazing job. Other mechanics in the shop were equally amazed. The cylinder broke in very well.