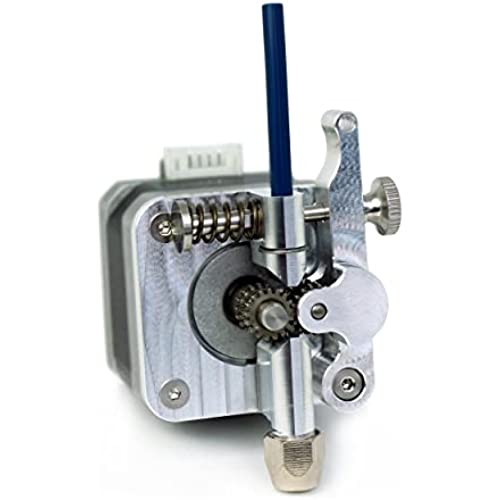

Micro Swiss Bowden Dual Gear Extruder Compatible with Creality Ender, CR10, CR-10 Pro, CR-10S, CR6-SE, Tornado

-

Edward N.

> 24 hourI got this as an upgrade for my CR-6 SE so I can print Carbon Fiber PC as well as getting rid of the plastic extruder that came with the printer. My printer has a filament detector on it, but the install instructions direct you to where you can print out the extension plate to make it fit. Note, only a few models need that printed, not all. Setup was simple, they provided all of the screws and pieces that are needed. Drop in and go. Even eStep calibration is simple. The power and precision that the dual gears provide really do wonders. Prints have became more consistent and the dual gears are strong enough to handle anything. I would recommend this product. If I get a 3rd printer, Ill get another one of these.

-

Tim Kauble

> 24 hourCouldnt be happier with this extruder. Install was straight forward, it bolted right up to the stock extruder plate and motor. Be aware there isnt a place to mount a filament runout sensor, so this will require a custom part of some type. The runout sensor is a slight hassle, but the quality of prints, ease of getting a great first layer, and the extruder clicking sound going away is more than worth it. Honestly, this should be a no-brainer upgrade for anyone looking for a better printing experience.

-

XYZ

> 24 hourI was having problems with extrusion on my ender 5 plus. Soon as I installed this and set everything accordingly done and over. No more problems.

-

Ken Nabbe

> 24 hourAs part of the installation, you need to cut the bowden tube from the extruder into a 45 degree point. That was annoying, trying to bevel it correctly. I would have preferred an included tube, with the cut already made. Other than that, it works well with PLA, Nylon and TPU.

-

czaky

> 24 hourHigh precision CNC parts. Much thinner than comparable dual-gear extruders, yet much more stable. Looks are awesome. Installation involves reversing the direction of the stepper motor. If you have a filament sensor, print an adjustment ahead, given the entry port is moved. You may need a longer Bowden tube replacement as well.

-

Eric

> 24 hourThis is an excellent extruder and has given me zero issues. I picked this up (along with an enclosure) to be able to print TPU on an Ender 3 V2 with a Capricorn PTFE tube bowden setup. It is easy to install being a direct drop in replacement for the stock Ender 3 V2 extruder which is infamous for failing. I did not have any issues with my stock extruder, but opted for this one to enable printing TPU and to get ahead of the stock one eventually failing. It is easy to adjust tension for different filaments, even on the fly. Loading/unloading filaments is night and day different to the stock extruder. This one handles most imperfections easily. If you would like to be able to print flexible filaments but are not sold on direct drive, or just looking for an extruder upgrade that is a direct replacement this is an excellent option.

-

bp

> 24 hourOn one level this extruder is silly... for $50 more you could move to a direct drive system and be done with it. But if you have an older 3d printer that you are largely happy with and just want easier changing of filament or better control of extrusion, this is about as good as you are going to get. Everything on it from the tension adjustment to the piece of tubing which guides in new filament just makes more sense on this extruder than it does on any other. Really this extruder is a critique of every other extruder I have ever used. Really it works great. For example I am printing out some vase-mode models while intentionally using over-extrusion (0.6mm line width through a 0.4mm nozzle) and it does not miss a beat at the printers standard speed. It just happily pushes filament. Installation is easy except for cutting a notch in the Bowden tube. Some kind of guide or jig would have made that a lot easier. That being said, I did manage to do it with filament snips, so I cant really complain. Combined with a BLTouch and OctoPrint, I have removed all the things I found annoying about 3d printing and am enjoying everything much more. On the other hand, for the amount I have spent on upgrading my Ender3 Pro I probably could have just bought a better 3d printer to begin with!

-

Katie

> 24 hourMy Anycubic Predators came with a 3:1 gear ratio extruder, which had gears and bearings and a lot of parts. The original extruder had a very high steps per mm (430), which gives it great resolution. One of the bearings disintegrated and I bought the micro swiss extruder to replace it. The micro swiss has a lot lower steps per mm (139), which is a lot less resolution, but it is built really well and has a lot less parts. For what i do, i favor reliability over precision. Time will tell, but im betting that the all-metal construction and simplicity will make it last longer than the OEM extruder. After printing with it, i dont see a noticeable difference on the benchy between the original extruder and the micro swiss. I have a feeling that the lower steps per mm on the micro swiss are still high enough to prevent visual defects. Seems like a great value to me!

-

_Set

> 24 hourI have used Bowden Direct Drives for years. This is a nice add on or upgrade.

-

Douglas Hillman

> 24 hourGot my E5+ a few months back. Research had informed me that the stock plastic extruder was a weak point. Decided to get a replacement right off the bat. I wanted a dual gear Bowden and not red, so this fit the bill. :) I hadnt gotten around to installing it yet when my stock extruder broke after just three weeks. Realized then that I had a stepper motor with a pressed on gear. I could have muscled the gear off and milled a flat onto the shaft for the set screw in the new gear, but I just ordered another stepper instead. Theyre cheap and it doesnt hurt to have a backup. An E5+ will need a printed bracket to reposition the stock filament runout sensor if you want to keep it. If you dont have another printer and havent printed one before you need it, you can just stick a piece of scrap filament in the sensor and lay it aside while youre printing the bracket. The listed 130 steps resulted in a good bit of underextrusion. Based on measurements and the calculations on the Teaching Tech calibration web site, 137 is the proper number on my machine. Overall, a very well-made piece and a good upgrade, even over the metal extruders on some machines.