Brush Research FLEX-HONE Cylinder Hone, GB Series, Silicon Carbide Abrasive, 4-1/8 (105 mm) Diameter, 240 Grit Size

-

zeek

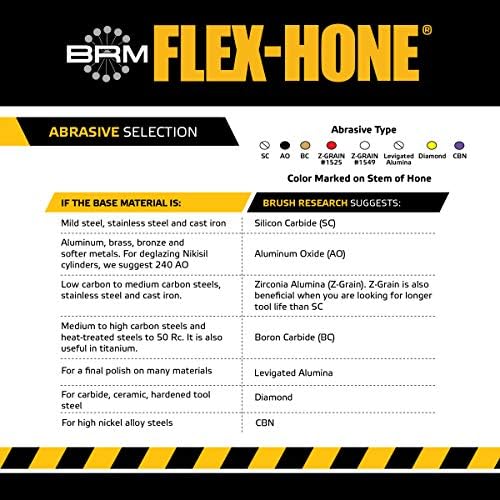

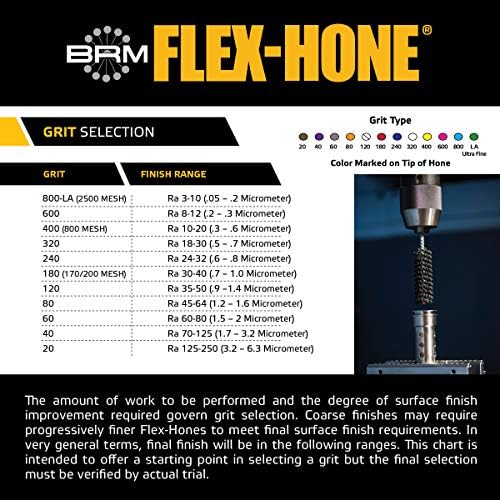

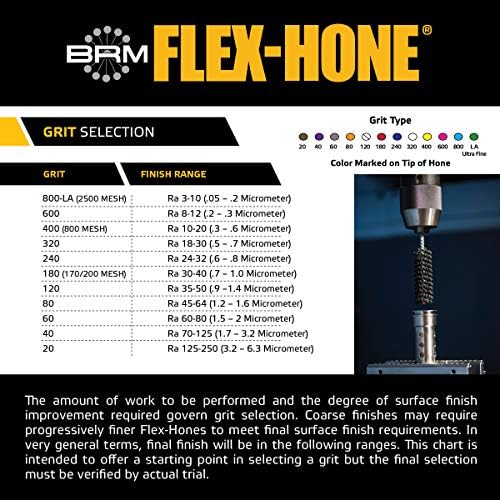

> 24 hourUsed to clean surface rust from the inside of the stick cylinder on a case 580c. The rust was light so I needed a home that would not cut in to much and leave the bore rough. I used a 240 grit 4-1/8” diameter hone. The finish was not that rough but I probably should have moved up to the 320 grit.

-

S. Ziemba

> 24 hourI bought this for my 1997 SeaDoo Speedster engine repair. I originally honed it with this but then found out I needed to get the cylinder bored over for other reasons. I took it into the machine shop and the machinist was in awe how amazing the cylinder looked he was wondering why I was even there. The cross hatch this tool leaves is second to none. This is a must have for anyone who regularly works on engines, but keep in mind these are fitted for specific size bores. If you just need one for a different size bore every time on new engines you work on, it might not be cost effective for you. For me, I would rather accumulate a whole set...so its all good for me.

-

Joseph vor

> 24 hourGreat tool, used this on a 305 chevy and made a excellent hone on each cylinder, even and consistent on each cylinder.

-

Rory Boehm

> 24 hourRecieved way sooner than expected. Very happy. Thank you!

-

Darren M. Lyall

> 24 hourPut a great cross hatch pattern in bores for new rings. the end is a littel trickey to center on drfill so pressure is the even throught the honing process. Make sure you line it up first before use ( very important).

-

TJ Bish

> 24 hourIt worked well for my SBC. I thought it should last longer than 1 V8 engine honing. Maybe its not supposed to, I dont know when I was done I noticed the dingle balls were smoothe.

-

June Runte

> 24 hourWorked wonders!!

-

Mike G

> 24 hourDid a quick hone of the cylinder walls while refreshing the engine over the winter, Bore size on my motor was 4.030

-

Russell Williams

> 24 hourThis flex hone worked well for aircraft cylinder engine cylinder finish, and honing out some scratches and score marks. Well packaged and appeared to be well made.

-

Jason R Dragun

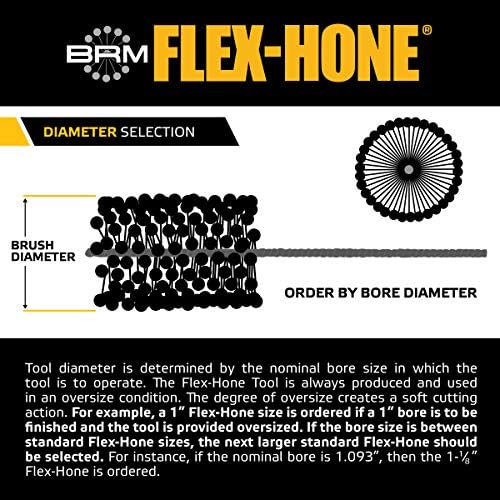

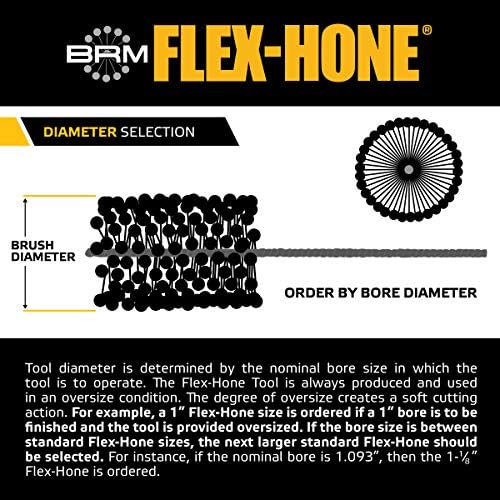

> 24 hourWorks excellent may seem to big or tight but its supposed be that this is for a 3in cylinder bore