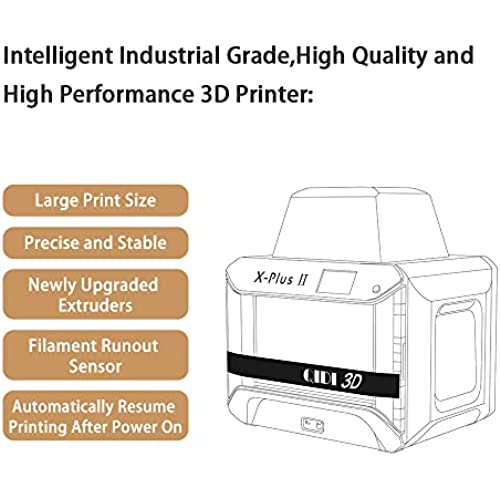

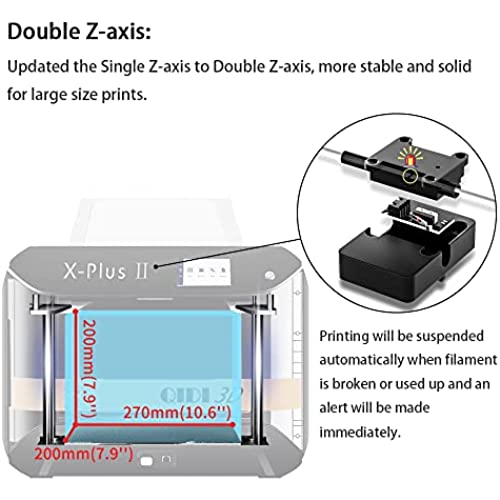

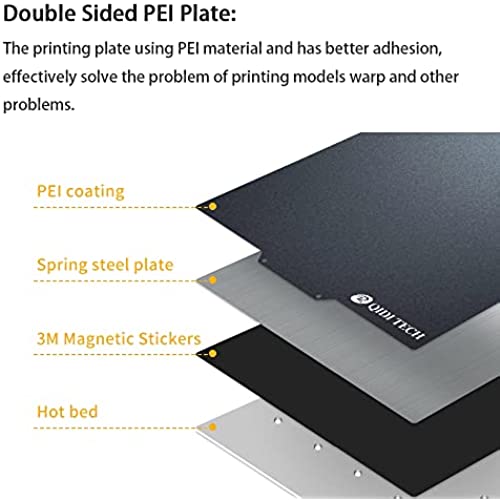

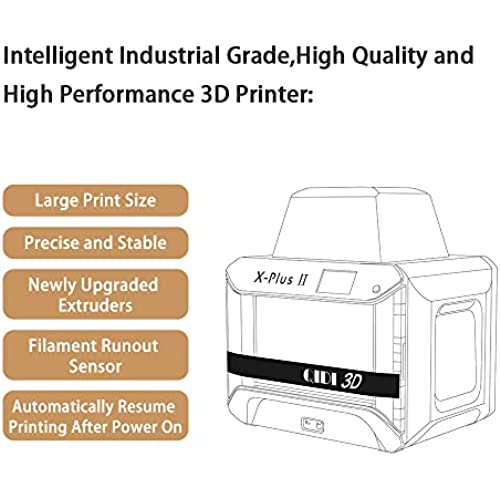

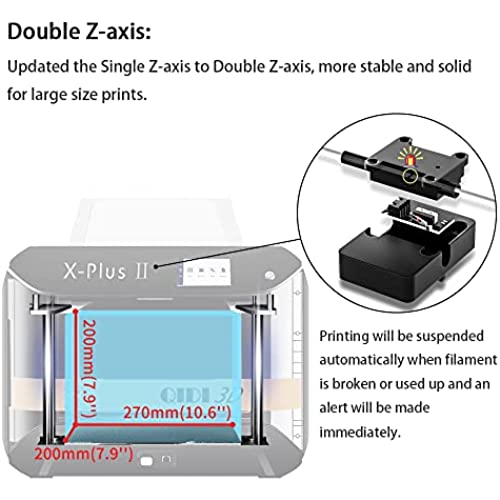

R QIDI TECHNOLOGY X-PlusⅡ 3D Printer, New Upgrade Intelligent Industrial Grade 3D Printers,Large Print Size,Printing with Nylon, Carbon Fiber, PC,High Precision Printing,10.6x7.9x7.9 Inch

-

David H. Youden

> 3 dayThe QIDI 3d printer arrived quickly. It was packaged to perfection - better packaging than most everything that I have purchased. I followed the setup procedure, and cut the test part with no issues. Since then I have printed several parts including one which took seven hours. All turned out exactly as expected, and I am a newcomer to 3d printing. I highly recommend the QIDI TECH X max.

-

Artworkspin

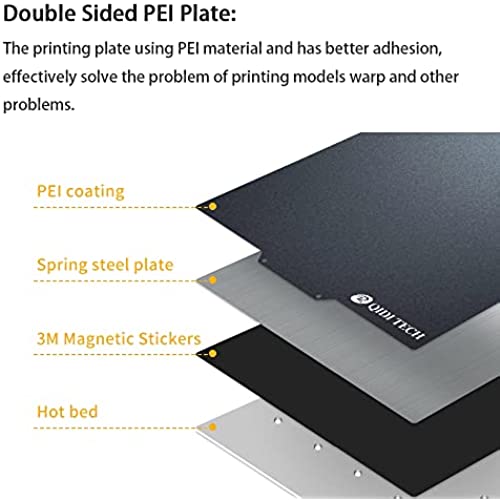

Greater than one weekThis is my first 3D printer and Ive had it for a little over a month. I have a CNC machining background so this wasn’t a huge leap. I plan to use it for more advanced plastics and the included enclosure and high temp print head was appealing, but I havent gotten that far yet. I can say it makes exceptional prints in PLA. The textured side of the removable bed works great. I flex it a bit and then use a razor scraper to free prints. Documentation on setup was written by a non-fluent English speaker, but it’s was good enough for me. Printing over wifi works fine from their slicer, but I prefer Octoprint. I can confirm that you can connect Octopi to it, but its not straight forward and you cant use the USB port on the front. You have to buy a +3.3V USB to serial adapter (https://www.amazon.com/gp/product/B07RBKCW3S), turn the entire unit on its side, remove the bottom housing, install the adapter, route the cable out the back, and then you have to install some user forum patches (google “x-max octoprint”) on top of Octoprint. Involved, but it worked. I havent tried running it over Ethernet (where the port is inconveniently placed on the front). The touch screen user interface could be a bit clearer. Its hard to identify between buttons and menu labels, as everything looks like a button. Once you know what to press its fine. The touch interface is pretty smooth over all, but I had issues setting up the wifi initially as it was really sluggish and froze, but eventually got it working. It comes with a USB flash drive that has to remain in the unit at all times when printing, even when using wifi. Thats kind of annoying, but more concerning to me is that the drive sticks out far enough that Im concerned that I may bump into it, potentially breaking it. To fix this problem I purchased an ultra mini SanDisk 32GB Ultra Fit USB 3.1 Flash Drive, but the 3D printer wouldnt even boot with it, even though the flash drive appeared to work ok elsewhere. I was confused and thought I had damaged the printer somehow, but putting the OEM drive back in made it come back to life. I tried again with a Lexar JumpDrive S47 32GB USB 3.1 Flash Drive and that worked flawlessly. It really didn’t like that Sandisk drive. I wish it had auto-bed leveling or at least the option to add it, but it doesn’t. You have to level the bed manually and there are two modes, a full and quick. You do the full level once and then do the quick one there after for the most part. The quick leveling is easy, but I’d still rather have auto-bed leveling. As far as build quality, its pretty good. Most of the housing is injection molded and fairly rigid. The mechanical components look good. The rear panel is either vacuformed or rotationally molded and is kind of flimsy (it’s only a cosmetic cover). The only manufacturing issues I had were the internal spool holder had an over-molded bolt that wasn’t in straight (fixed with a heat gun) and the top clear cover didn’t seat perfectly so the magnets didn’t hold very well (fixed with a furniture scraper; the magnets are kind of pointless anyway). Neither defect would not have impacted the function of the machine. Design-wise the spool holder works, but the retention clips are flimsy and I wish there was less drag on the spool. Overall, I’m happy with the machine and I may buy another one if the high temperature stuff works out.

-

andylibby

Greater than one weekI did a lot of research before buying the X-Plus and Im glad I did. I learned three things: 1) That it was easy to use, 2) That the print quality was above average, and 3) That Qidi customer service is responsive and capable. I unboxed everything and followed all the directions, but had problems with the display screen and the print bed z-axis rod. I sent an email to Qidi and had a reply with answers and video instructions on what to do in a couple of hours. I was printing my first part less than an hour after that. Plus, this thing is quiet! I can hear the fans softly and nothing else. Ive been around other 3D printers that are super noisy. Not the X-Plus. I’ve got months and hundreds of printed parts under my belt now with the X-Plus and I continue to be impressed with its simplicity, durability, ease of use and low cost.

-

Scott Turner

> 3 dayIm new to 3D printing but Im really satisfied with this QIDI TECH X-Plus. Its very well made and QIDI-Techs support is excellent. I had one issue with a print, but Sophia helped me resolve the issue with a firmware upgrade. She also was quick to answer my question about their slicer software QIDI-Print, which by the way is very easy to use and works quite well. I would highly recommend this printer.

-

MW

> 3 dayVery solid machine on the hardware side but needs some dialing in and support has your back.

-

Edward B.

> 3 dayThis is my 2nd X-Plus and Im very satisfied. Setup is easy and I was into production printing in less than 1 hour. Technical service is fast and very helpful. If youre requirements are precision, high volume printing this is certainly a printer to consider.

-

oleg superman

> 3 dayThis is the BEST printer for the PRICE period. I have been using it for a month now and have CR-10 V2 that I can compare it to print quality, assemblies and over all experience. Let’s start with CR-10 V2 First. The printer came almost fully assembled took me about 30-45 min to set it up and start running my first prints. Since this is my first printer CR-10 V2 it is, I took me about 2 weeks to figure out how to print. First I had layer adhesion problems then bed level. I had to learn all that before my prints start to turn up somewhat okey. They model that they provided on the memory card printed perfect but my prints were failure after failure. About 2 weeks into it I finally figured it out and started to print! My abs prints and PETG were warping and made those prints as a complete failure or somewhat deformed. So I built the in-closure Box for it which turned out to b huge because of the build volume that CR-10 V2 provides the hight of 400mm. So the prints start to turn up somewhat good. The problem with that though it shuts off at 258c if u trying to print high temp filaments. So I ran into temp limit. I know that I could of changed hot end and get it to higher temp but I got no experience to do that and because it is my first printer I was afraid of breaking it. So I start to upgrade it a little by little, first I got BL touch sensor for bed leveling that comes with instructions and video how to set it up. After I tried to set it up for 3 6-8hrs days I failed and still can’t get it to work I contacted creality, first they respond like 5 days later second they want me to video the whole procedure of the fail and saying that it might b a wire problems and to video wire diagram on the main board and the sensor along with the flashed firmware. But because it’s a failure and now it’s in the in closure it’s not an easy job to do just to make a video for them for the failure that they have. So then they came up with a titanium direct drive bolt on upgrade for the CR-10 V2 that I got from their own creality website. After installing it the drive were instead of feeding the filament into hot end it actually spit it out. So again there is wire issue that I had to figure out with a risk of burning the printer down. At the end I figured it out and switched wires pins and it started to work. So with the do it urself box material that coast me 130$ plus bl touch sensor 59.00$ plus direct drive 65.00 plus printer 540$ Lots of time patients and frustration u got a printer that BL touch auto bed leveling that still don’t work with a direct drive and a crappy box in-closure 800$ printer. Finally here come QIDI Plus-X. Comes completely assembled. U start print in 15 min. After my first print I had failed and my print got stuck to the built plate so hard that I ripped off the chunk of the plate trying to remove the print. It happened because CR10V2 and QIDI level their beds in completely different way. While CR10 V2 needs the paper to have lots of friction on it between hot end and plate QIDI printer needs just a slight friction. So I contacted the QIDI and they sent me 2 New print beds within next 2 days but while I waited for it to arrive I was printing on the same bed just flipped it on the other side because they have 2 sided magnetic flexible bed which is AWSOME! Anyways about of month printing I had like 3 failed prints and it’s totally my fault because I were using same setting that I used for CR10 but after I updated their cura based slicer to the newest version I start to use just that. And I made a comparison between 2 printer that r having same settings same infill/hight etc one is sliced on cura 4.5 and the other is on QIDI slicer and QIDI prints comes out 30% quicker and better quality ! I really got a lot more to say but I am afraid that no one will read it. In conclusion. U will not find a better printer then QIDI tech for the price and what it’s offers with 2 different hot ends/inclosure/ bed level assistant and WiFi file transfer from ur computer and u can Adjust temp/speed/stop or pause wirelessly from ur computer. However it does not have runout filament sensor. But it got it have an option of fitting ur filament spool from inside the printer. I use it for printing abs. What it does is the inside gets temp up to 45c and the moisture drops to 10% it’s the same moisture %that my dry box produces and u don’t even need a dry box if u got QIDI tech. And it works like a charm. I have read some previous review about that inside spool holding location and ppl saying that it looks like it’s in the way or will not work, that makes me think they have never tried using that option. But for me this is the only option that I use. Unless I print with PLA that doesn’t matter about the moisture, which I usually print on CR10 V2 instead. This QIDI tech Plus-X I use for higher temp/abs/pc filaments prints and they r comes out fantastic. If u r looking for a printer that u want to print and print well without timkering it to make a good print this is a printer for u. Just make sure u upgrade to the NEWEST slicer directly from QIDITECH3DPrinter.com website and u r set! U will not get disappointed with this printer at all. There is nothing better for this price on the market as of 3/4/2020. I did a month long search and research. And to find printer under 1000$ that print temps up to 300c fully good looking professionally in-closed/wifi with touch screen that projects the part that u r printing on the display that is on the printer with the best costumer service that gets 5 out of 5 starts doesn’t exist. Even on E3D website review it rated number#1 printer and only then on second place goes Prusa MK3s and I will have to agree with them. I still print on in every single day with “0” issues. This is a highly trained work horse. If u got any questions I’ll b gladly answer them for u. Unless it’s something weird or I don’t know the answer to it. Ha ha ha jk. Have a great day folks. P.s. this “ Rick the pickle “ print is done on QIDI tech PLUS-X with ABS+ 200mm high On 0.2mm layer high and the quality as u can c if just great even 1mm teeth r printed perfect. There was no sanding done to it just primer so I can paint it and on the lift leg there is one tiny part is broken off because I was taking off supports too quick. But the arm is about 2mm wide support as u can c and it printed that just great. Hopefully that helps u make a choice and no I am not sponsored by QIDI tech. I wish I were but I am not just a regular costumer just like u... P.s. made this print for the outside light, because when I was installing it originally I dropped the glass that came with it. So I printed one on QIDI tech X-plus with rick on it if u take a closer look u will c it. This if from show “rick and morty” printed with transparent PETG.

-

Amanda Jones

> 3 dayThis is our first 3D printer…we’ve had it for a little over a year. It continues to perform flawlessly after appropriately adjusting the z offset. Upgraded magnetic print bed. Super happy with our purchase. My daughter is into clay sculptures and 3D anatomical models serve as an excellent base for clay modeling.

-

D. Harrington

> 3 dayI received the X-Plus as a gift from my wife. Ive not used a 3D printer before but I am fairly experienced with basic 3D modeling using Sketchup. Unpacking and set-up didnt take long and I was printing my own creations within hours. I love this printer. I had no issues getting it up and printing. The most difficult part for me was figuring out how to remove the internal packing material. After getting past that, the only additional set-up was to remove a couple of clips securing the print head, load the filament, plug it in and print the test piece. There were a couple of minor issues out of the box but they did not affect the function and Qidi resolved them painlessly. Ive only used PLA so far but have the ability to use a wide variety of materials. The printer is outfitted with removable sides, top and door so the printer can be used in open or closed configurations depending on the filament used. The printer comes with a low temp extruder installed and a high-temperature extruder that can be installed if needed. It also includes a spool of red filament, instructions, the tools needed for basic maintenance and also includes a variety of extra parts (nozzles, nozzle tubes, a variety of screws, filament guide tube, an extra magnetic print plate, level gauge sheet, glue stick, some electronic connectors that I havent figured out yet, and an ethernet cable). BTW, the printer connects via WiFi so the ethernet cable was not needed in my case. The case is heavy-duty and very sturdy, and the printer runs very quietly. I have it 5 feet from my desk and hold Zoom meetings while its running without noise interference. The printed instructions will get you set up and printing but they are not super detailed. However, Qidi provides additional documentation on an included thumb drive that contains lots of video instructions. Dont overlook those, it took me a while to realize they were there. Also, Qidi has very responsive customer service. My experience with the X-Plus so far has been excellent and I highly recommend it. BTW, the picture includes some mods I made to the printer (added camera and light brackets (printed, of course), printed a different filament rod yolk that works better for me, and I strengthened the aluminum tube to hold two spools (it broke when I tried that without additional support).

-

Ross M Gardner

Greater than one weekThis printer is awesome... incredible print quality, and the range of materials due to the high temp capabilities is another big plus for me. Tech support is good and they have videos/detailed instructions for most operations and common problems. They are based out of China so direct communication may not always be completely fluent, but not bad. For the money especially this printer is hard to beat.